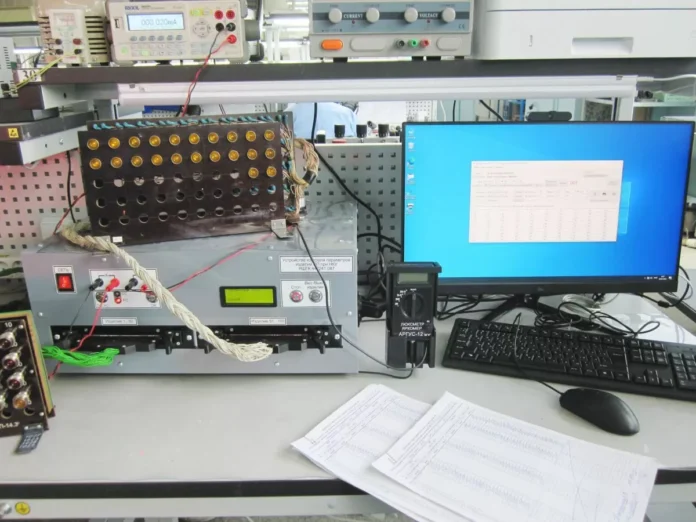

In June, with the efforts of the Scientific and Technical Department (NKIO) and the active participation of the leading design engineer of the Experimental Design Bureau «Indicator», a semi-automatic device for monitoring the electrical parameters of products IP and SKL under normal climatic conditions was installed in workshop No. 36.

This innovative device was developed by the team at OKTB «Indicator» and is a significant step forward in ensuring the quality and reliability of our products. It is designed to accurately measure and monitor the electrical parameters of our products, ensuring that they meet the necessary standards and specifications.

The installation of this device in workshop No. 36 is a testament to the dedication and hard work of the team at OKTB «Indicator». Their expertise and knowledge in the field of design and engineering have made this project a success.

The semi-automatic device is equipped with the latest technology and is capable of performing a wide range of tests on our products. It can measure parameters such as voltage, current, resistance, and capacitance, providing us with accurate and reliable data.

One of the key advantages of this device is its ability to operate under normal climatic conditions. This means that it can function effectively in a wide range of temperatures and humidity levels, ensuring that our products are tested and monitored in the same conditions in which they will be used.

The installation of this device in workshop No. 36 will greatly enhance our quality control processes. It will allow us to detect any potential issues with our products at an early stage, ensuring that they are fixed before they reach our customers. This will not only save us time and resources but also help us maintain our reputation for delivering high-quality and reliable products.

Furthermore, the semi-automatic device is user-friendly and easy to operate, making it accessible to all employees in workshop No. 36. This will not only improve the efficiency of our testing processes but also provide opportunities for our employees to learn and develop new skills.

The success of this project would not have been possible without the support and collaboration of the NKIO. Their expertise and guidance have been invaluable in the development and installation of this device. We are grateful for their continued support and look forward to working with them on future projects.

In conclusion, the installation of the semi-automatic device for monitoring electrical parameters in workshop No. 36 is a significant achievement for our company. It showcases our commitment to continuously improve and innovate in order to provide our customers with the best possible products. We are confident that this device will play a crucial role in maintaining the high standards of quality and reliability that our customers have come to expect from us.